The Science of Measurement

Understanding the Origins of Metrology

The term metrology originates from ancient Greek, combining “metron” (measure) and “logos” (treatise or discourse). It is the science born from humanity’s need to quantify the world with precision, ensure the validity of those measurements, and establish their universal acceptance.

A Fundamental Part of Everyday Life

Measurement is deeply embedded in all aspects of human activity—scientific, industrial, and commercial. Each day, often without noticing, we rely on it in countless routine actions. Metrology plays a critical and growing role in key sectors such as:

- Energy and hydrocarbons

- Health and medical sciences

- Communications

- Agri-food and pharmaceutical industries

- Industrial safety and environmental protection

The Importance of Accurate Measurements

One of the oldest expectations from vendors is to give “honest weight and measure.” Whether it's a seller knowing exactly what they are offering or a buyer receiving exactly what they paid for, trust is built on accurate measurement. In today’s world of mass-produced, pre-packaged goods, accuracy remains just as essential—for instance, a 500g packet should contain 500g of product, no more, no less.

A measurement—be it the weight of a bar of soap or the temperature at the outlet of a boiler—must be consistent and meaningful across time and place. This consistency is achieved through the regular calibration and verification of measuring instruments, ensuring they are aligned with international reference standards. This traceability makes the measurements reliable, valid, and universally recognized.

The Birth of Modern Metrology

Metrology, as a formal science, emerged in the 19th century during the industrial revolution. As global trade expanded, the need for standardized measurements became evident. The Metric System, initiated by a convention signed in Paris in 1840, laid the foundation for this unification. Today, the International System of Units (SI) serves as the global standard, ensuring all measurements are traceable to universally accepted references.

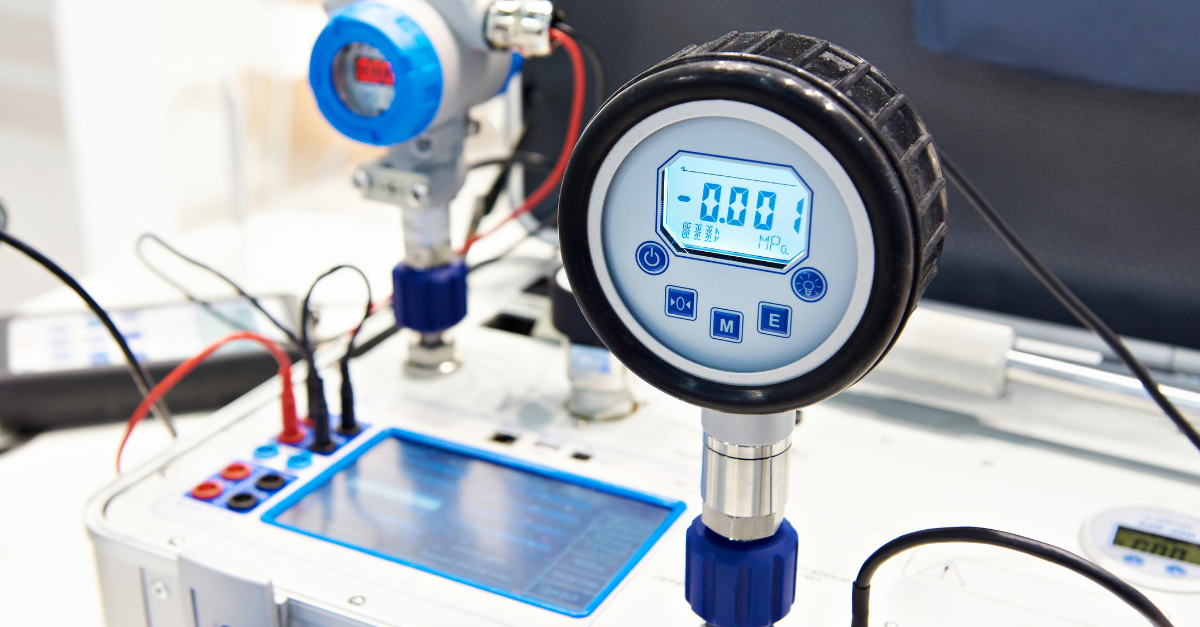

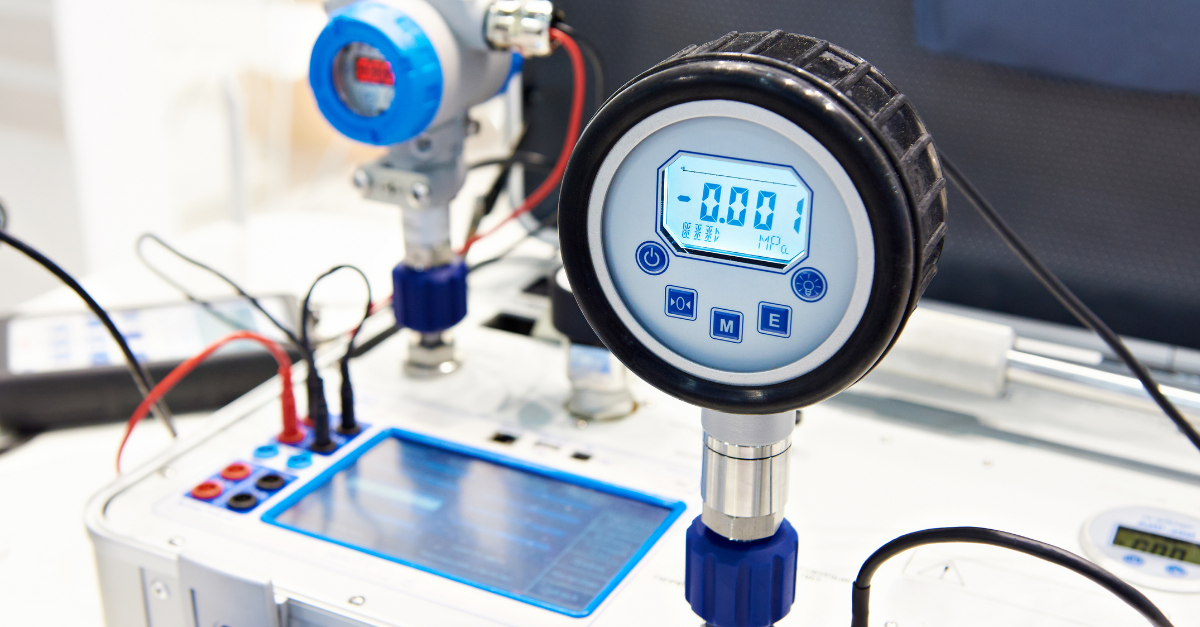

Measurement: A Pillar of Industrial Quality

In industrial settings, production processes rely heavily on instruments that measure pressure, temperature, weight, flow rate, and dimensions. The accuracy of these instruments directly influences:

- Product and service quality

- Operational safety

- Risk management

- Environmental compliance

In high-stakes sectors such as pharmaceuticals, agri-food, and petrochemicals, controlling measurement instruments is not optional—it’s a regulatory necessity. These tools must be accurately maintained and monitored to stay within acceptable error margins.

Global Compliance and Market Access

Regional harmonization of laws (e.g., in the EU) and the growth of international standards have introduced new technical requirements. Major markets—such as the European Economic Area (EEA)—are now protected by non-tariff barriers that enforce strict product and quality standards.

Among these are metrological requirements. To gain market access, businesses must prove that their measuring instruments are compliant and traceable to SI standards maintained by the BIPM (International Bureau of Weights and Measures).

Standards That Demand Metrological Rigor

International standards like ISO 9001 (quality management), ISO 14001 (environmental management), and those related to industrial safety require organizations to control and calibrate their measuring devices. The objective evidence of quality depends on measurement—and trustworthy measurements require ongoing verification and traceability.

Internal and External Impacts of Measurement Control

For a business, controlling measurement tools is crucial for both internal efficiency and external credibility.

- Internally:

- To optimize production processes

- To ensure worker and equipment safety

- To limit environmental impact

- Externally:

- To pass audits for certifications

- To qualify for international tenders and markets

- To demonstrate conformity with industry regulations

Calibration: The Backbone of Reliable Measurement

Mastery over measuring instruments comes from regular calibration and verification. These processes link a measurement back to international standards, ensuring it is universally recognized, consistent, and meaningful.

A Regional Challenge and Opportunity

The challenge was clear: To design, document, implement, and manage the first scientific and technical metrology laboratory in the UEMOA region—a laboratory tailored to the needs of industry and fully compliant with international norms.